Poultry technology

The poultry test farm

The poultry test facility features three separate 526.6 m² housing areas, each designed as deep-litter, compartmentalized spaces capable of accommodating approximately 20,000 broilers per cycle. The building's design, architectural solutions, and integrated modern technology enable higher production standards. The feed storage and delivery lines, feeding and drinking systems, as well as the Dosatron-based medication dispensing system, are all tailored to test conditions while maintaining the characteristics of a commercial production site.

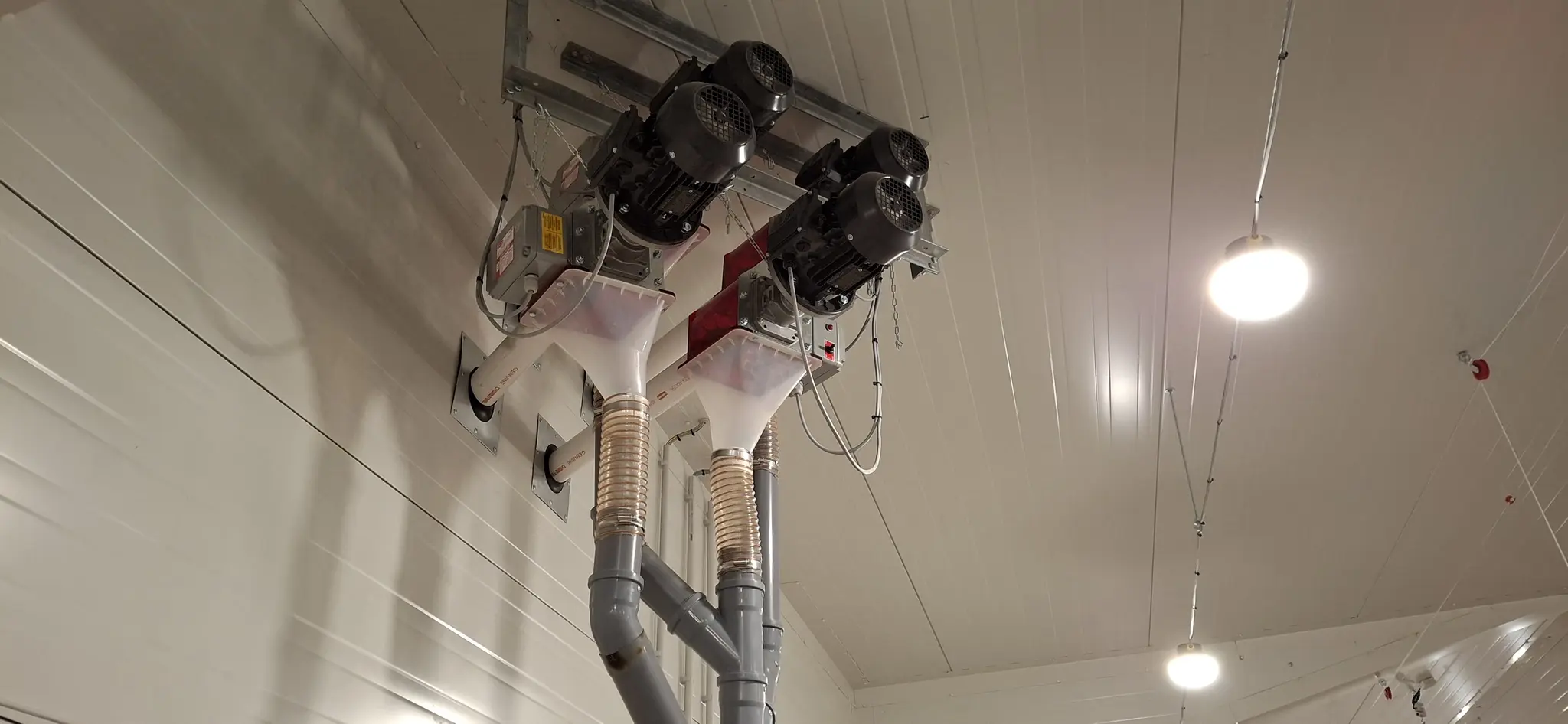

The buildings are climate-controlled, with heating provided by air heaters and cooling by cooling panels, all managed by computer-controlled automation. Ventilation for the facility is ensured by Euroemme cross-ventilation systems, which continuously measure air pressure variations around the barn and automatically operate air inlets without human intervention. Lighting is provided by the latest energy-efficient, adjustable fixtures, and the lighting cycles are managed by control computers located in the housing areas.

Data processing

When designing the housing areas, one of our main considerations was to ensure the collection of sufficient data with an adequate number of repetitions during the tests, enabling statistically evaluable results. In terms of layout, two barns were divided into 8 compartments per airspace, providing a total of 16 compartments capable of housing approximately 1,200 birds, depending on stocking density. With random placement, two treatments can be compared with eight repetitions for feeding tests conducted here. Each compartment is equipped with bird scales, and the ability to measure feed consumption allows for monitoring specific feed conversion efficiency.

In the third airspace, 24 smaller compartments have been created, each capable of housing 200 birds. In this barn, we can simultaneously test 4 feed types with six repetitions each. In this small-group barn, the weight of the birds will be measured using BAT1-type, manual, mobile bird scales in a suspended design. In addition to weight measurements, sufficient data on feed consumption and specific feed conversion efficiency will be available for statistical evaluation.

During feeding trials, we can test genetics, same-gender individuals in the small-group room, various feed formulations, feeding programs, and special feed additives. The necessary analyses of raw materials and prepared feed for the tests can be conducted in the parent company's laboratory in Szalkszentmárton using NIR rapid testing and chemical methods. We can also assist in developing feed formulations and statistically evaluating the data collected during cycles (weight, feed and water consumption, specific feed conversion efficiency).

The building design of the stables also allows, in principle, to run so-called "technologically provoked" tests, by choosing the temperature of the stables, the number of hours lit or the intensity of the lighting.

Goals

The primary goal of establishing the test facility is to continuously seek solutions to improve production results, reduce antibiotic use, and implement cost-effective measures, thereby contributing to enhancing the profitability of our poultry partners.

Barn areas

| Barn features | ||

|---|---|---|

| Description | 1-2. barn area (industrial broiler model) | 3rd barn area (small group broiler model) |

| Size | 2 x 526,6 m² | 526,6 m² |

| Compartments | 24 units | 16 units |

| Capacity | 200 units | 990 units |

| Feeding rows | 2-4 different | 2 different |

| Feeding system | Manual weighing | Automatic weighing |

| Properties of both barns | ||

| Feed intake | ✔ | |

| Live weight | ✔ | |

| Specific feed conversion | ✔ | |

| Water consumption | ✔ | |